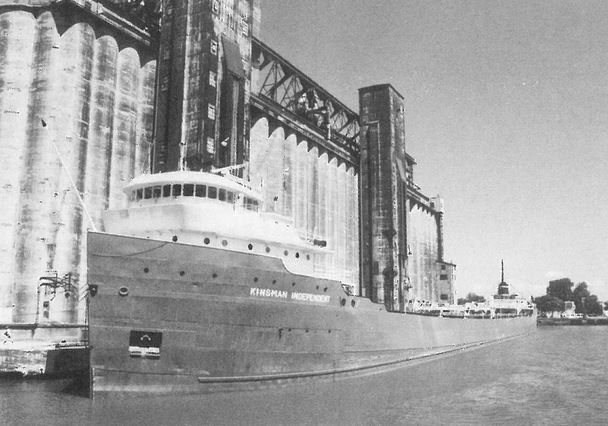

The Kinsman Independent, owned by George Steinbrenner, owner of the New York Yankees, finishes unloading at the Lake and Rail, June 2000.

WNY Heritage Collection

One by one bits of Buffalo’s grain elevator empire have gone the way of the dinosaur. Their bleached bones standing tall on the Buffalo waterfront, they include the Concrete Central, the Connecting Terminal, the Wheeler, the Great Northern and others. Recently another elevator, the Lake and Rail joined the group of closed and abandoned concrete silos along the Buffalo River.

The Lake and Rail Elevator was built in four steps over the years 1927 to 1930, reaching a total capacity of 4,400,000 bushels. Also in 1927, the International Milling Co. erected a flour mill to be supplied from the elevator. The elevator served to receive grain from lake boats and by rail and to ship out on canal boats (especially Welland Canallers), lake boats, by rail and later by truck. Business was often brisk. For example, in the period from 1950 to 1960 an average of 60 lake boats were unloaded each year.

As time passed the flour mill increased in size, becoming one of the area’s largest, but the transfer business decreased so that finally the elevator’s sole use was to supply the mill.

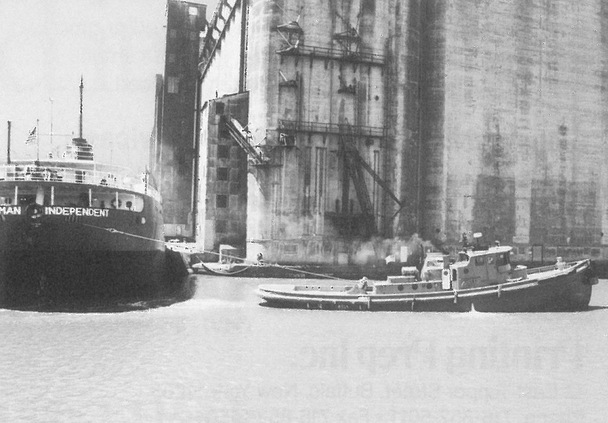

The Kinsman Independent leaving the dock at the sharp bend in the Buffalo River under tow by the Great Lakes Towing Co. tug New Jersey; to the immediate right of the tug is the long unusual flat wall facing the river.

WNY Heritage Collection

The elevator was built of reinforced concrete by the noted Kansas-based firm of Jones-Hettlesatter. The two marine towers are made of steel clad with corrugated iron and were designed and built by Buffalo’s Monarch Engineering Co. The bins were slip formed starting at a bin slab supported by columns from the foundation, a method that was in common use up until that time but was being superseded by a system where the bin walls were run up directly from the foundation. Facilities included scales for weighment of incoming and outgoing shipments, grain cleaners, a grain drier, a railroad car dumper to speed unloading, and equipment for loading out on trucks.

A major problem was the site, located at a sharp bend in the Buffalo River. In order to obtain the required capacity in the small space allotted for the elevator, its four sections were built at various angles to each other and the final section was built higher. Its silos at 150 ft. are the highest of any main elevator in Buffalo. The angularities and the height difference caused complications with the internal transfer system. This last section has an unusual flat wall facing the river. One part of it tapers along a railroad curve and ends in a single bin.

Around 1970 International Milling became International Multifoods and in 1988 it became Conagra. In April of 2001 it was announced that the mill would close in June. This has occurred but there remains a remote possibility of rental to another grain firm.